Roof Panel Construction

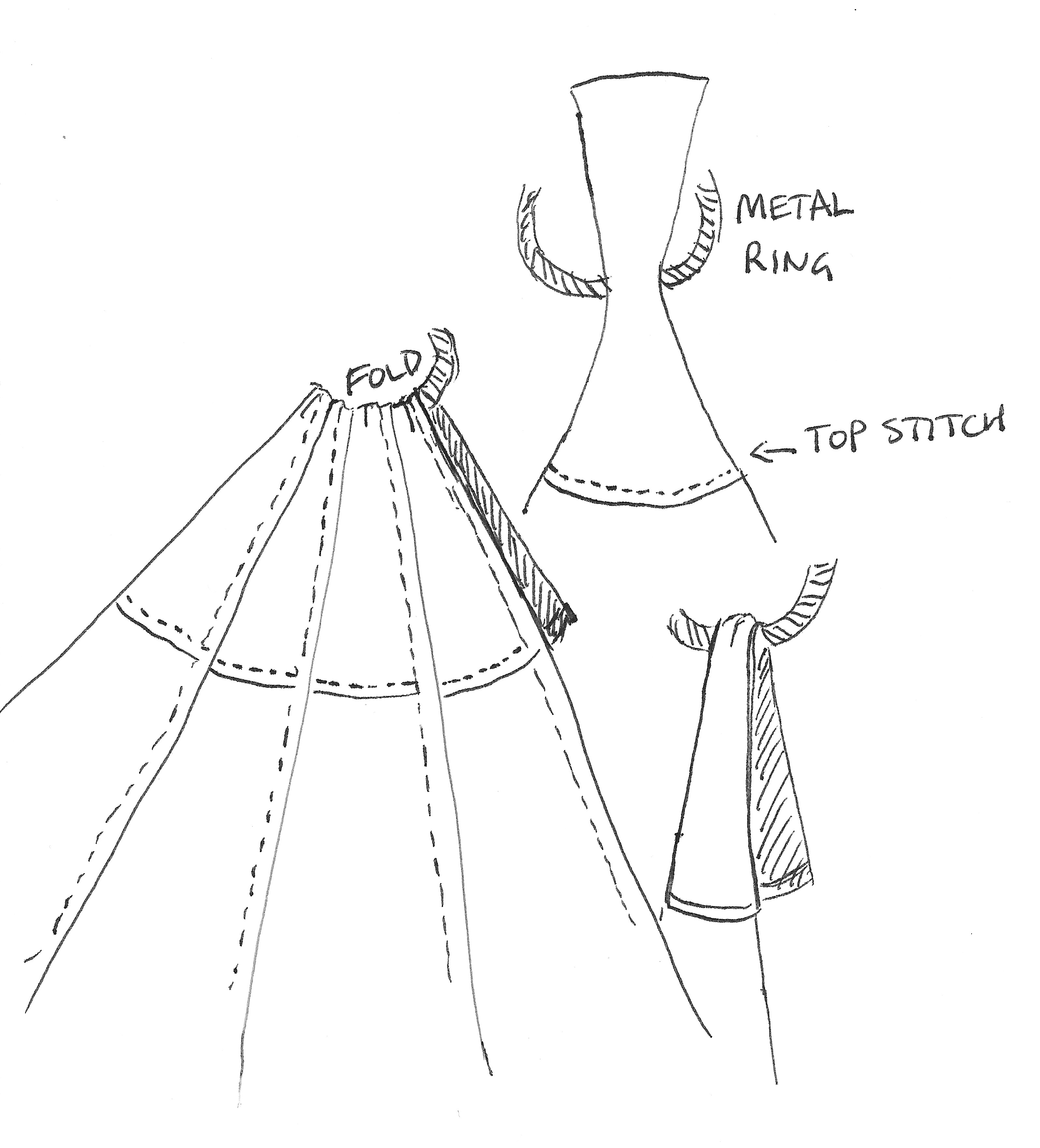

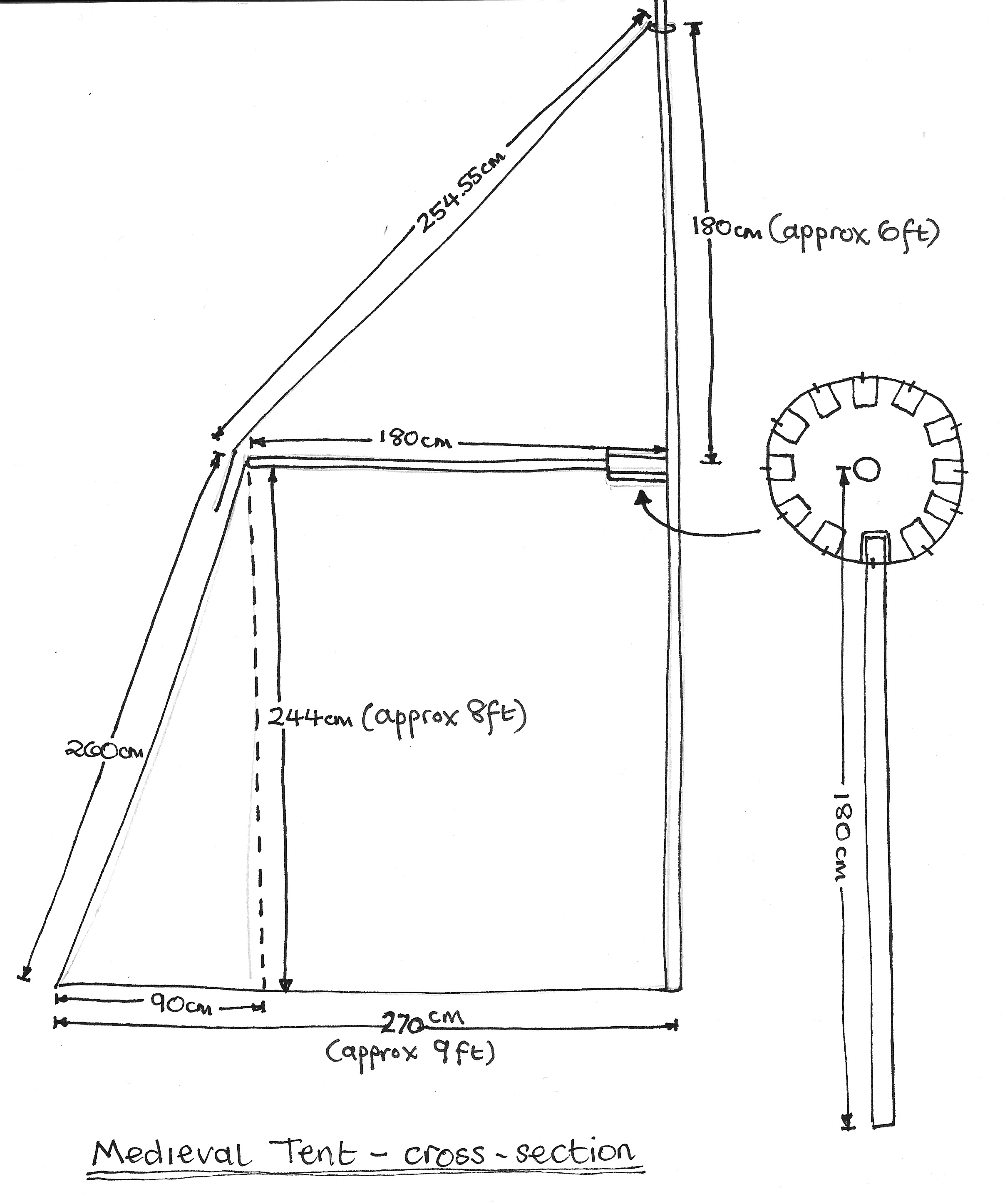

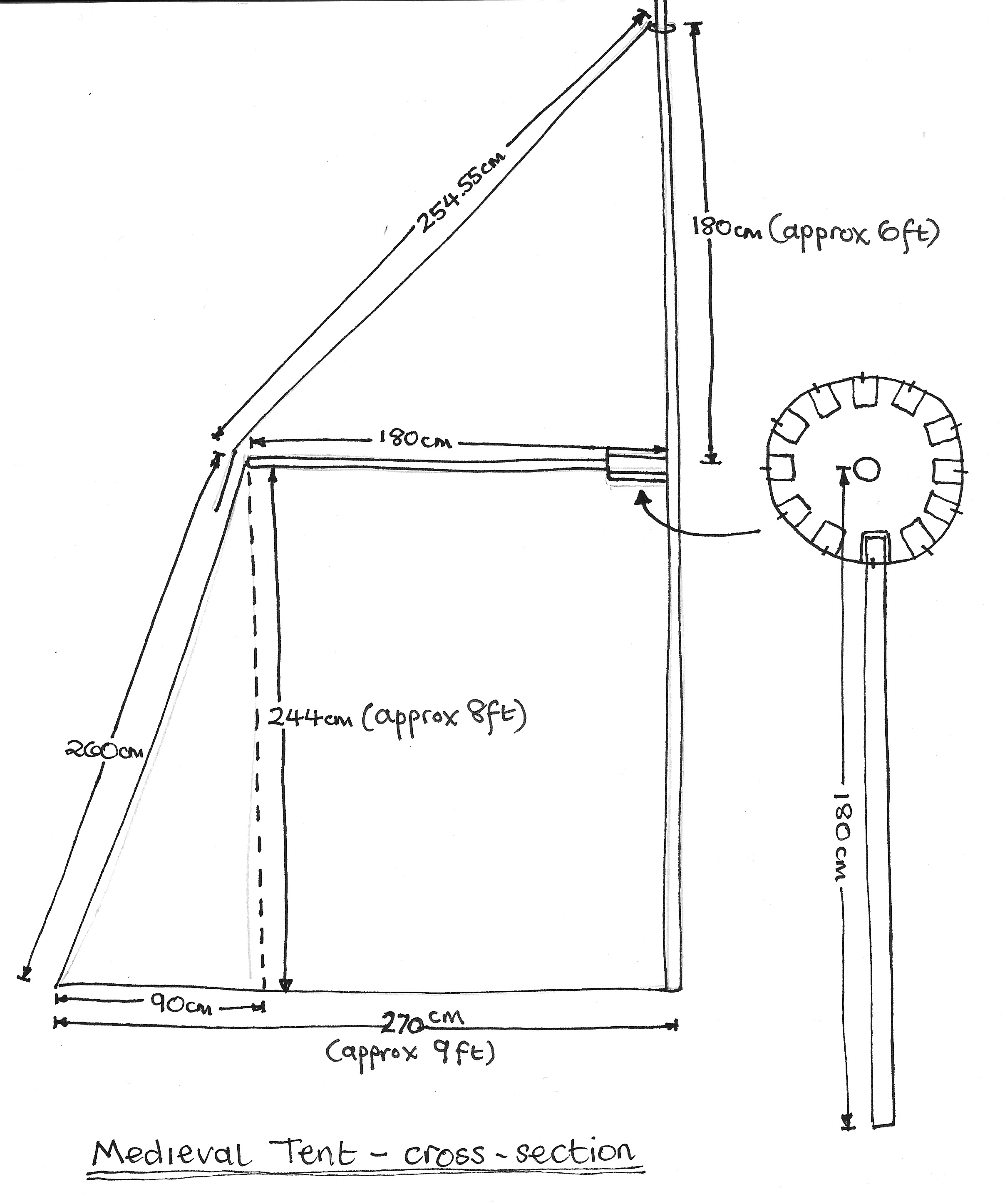

Having cut out the twelve roof panels using a the paper template made from our measurements as show on the diagram below, we now need to finish the scalloped edge and reinforce the top where the ring to support the roof on the pole will be fixed.

We have decided to line the scalloped edge to provide some extra strength when attaching the tapes and eyelets for the guy ropes and also to bulk it out so that it sits slightly proud of the main body of the tent. This involves carefully marking each panel, pinning these together, marking on the 2.5cm (1 inch) seam allowance and cutting out. Each piece will remain pinned to its own roof panel, twelve in all.

These are set aside.

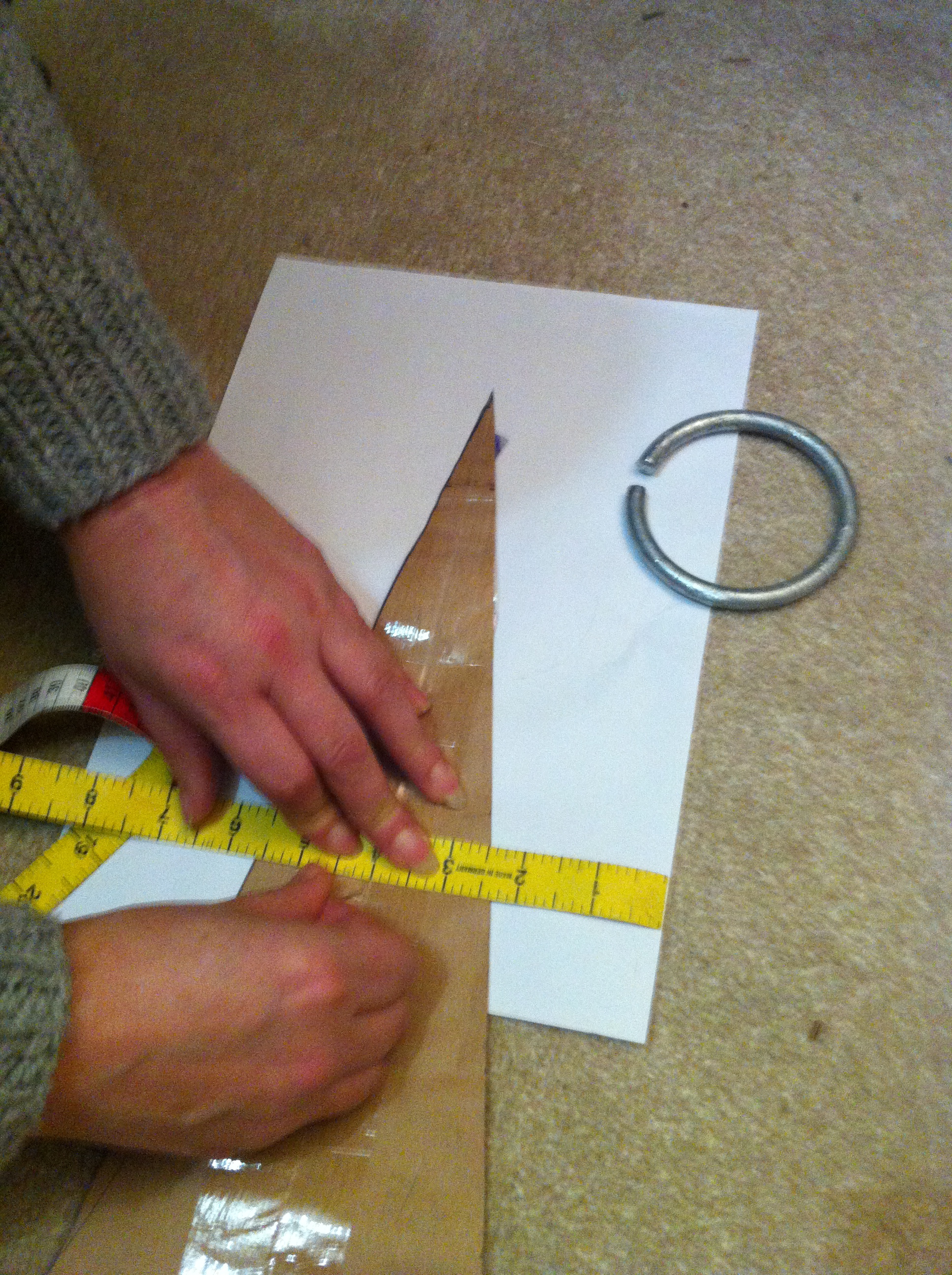

To reinforce the points of the roof panels to take the ring which will fit over the centre pole it is necessary to add fabric to pass through this ring folding it back down the panel and then hand stitch it on. We have found, in an ironmongers, a steel ring measuring 72mm internal diameter which we have calculated will take the fabric reducing the diameter down to approximately 50mm. The centre pole will need to be sanded down reducing its diameter from 75 to 50mm creating a taper to slide the ring onto.

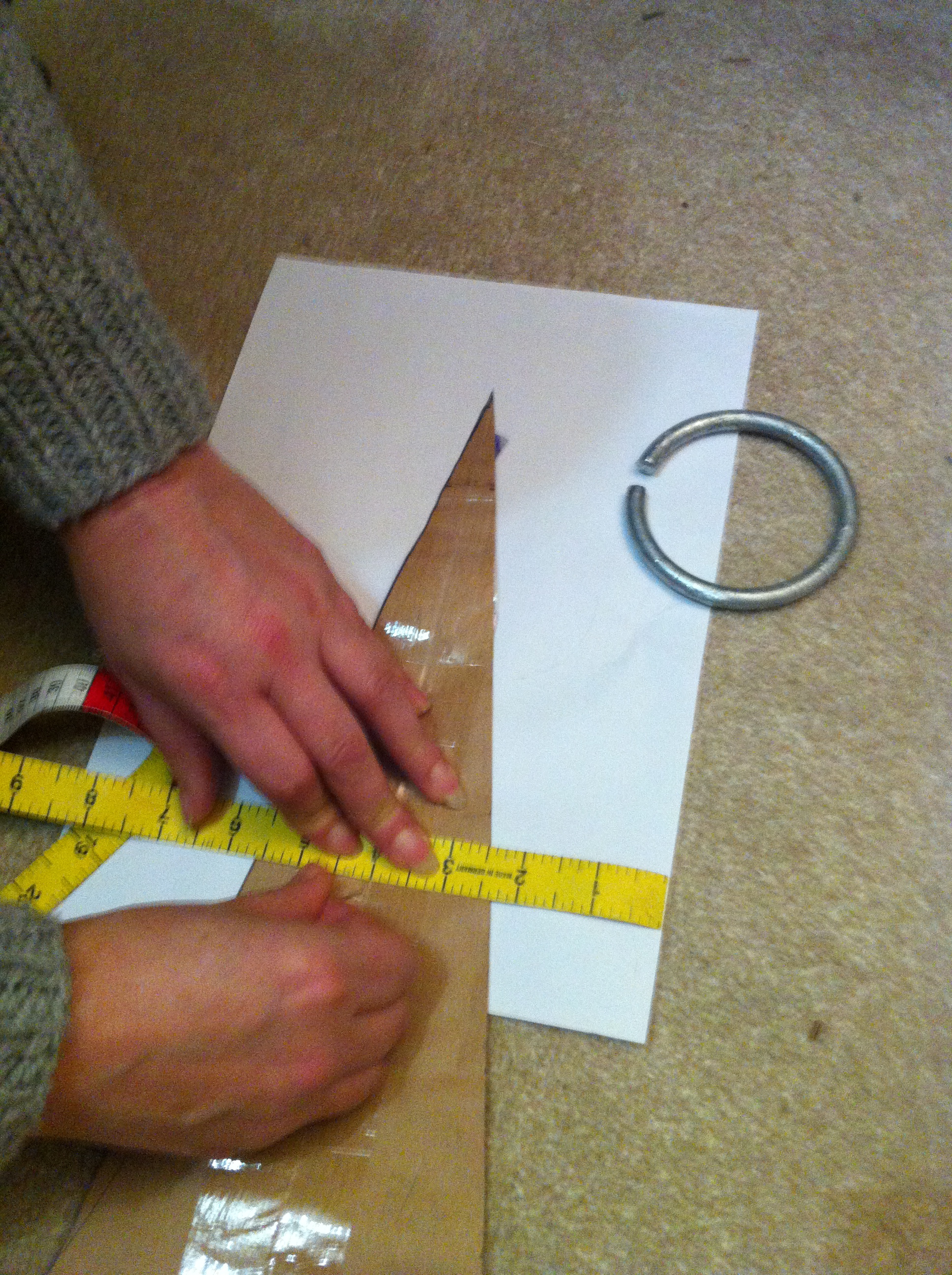

Marking the point of the roof panel to make the template for the reinforcing piece to attach the steel ring.

Pinning the roof template ready to cut out the reinforcing piece.

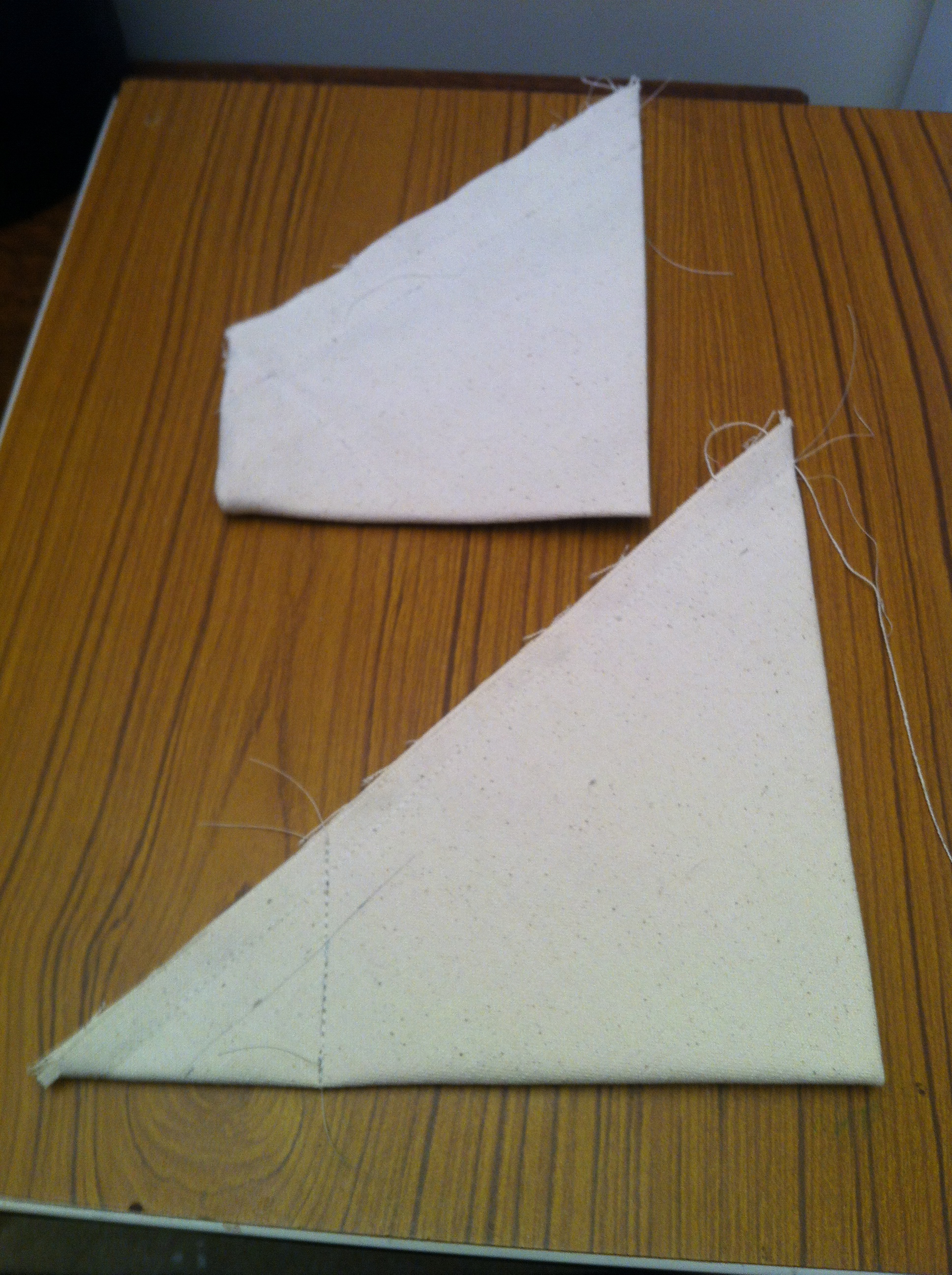

Once the template was cut out we marked twelve on off cuts of fabric ensuring that they all followed the weave in the canvas. A 25mm (1 inch) seam allowance was added to the sides with a 20mm (3/4 inch) seam applied to the curved edges top and bottom. These were set aside.

We are ready to construct the roof panels. Continue to follow our Blog to find out how we get on.